Customers also bought

Complementary products

Cabinet Grade Plywood: What You Need to Know

Look, after 15 years in this business, we've seen too many projects go sideways

because someone skimped on materials. When you're building cabinets, closets,

or custom furniture, your plywood choice makes or breaks the entire job. That's

why we stock only cabinet grade plywood at Berta Store.

What Actually Makes Plywood "Cabinet Grade"?

Here's the thing most people don't realize – not all 4x8 plywood is the same. Cabinet grade plywood uses Grade A face veneers, which means zero defects, no patches, and surfaces smooth enough for any finish you throw at them. Compare that to the B or C grade stuff from big box stores, and you'll see why contractors keep coming back to us.

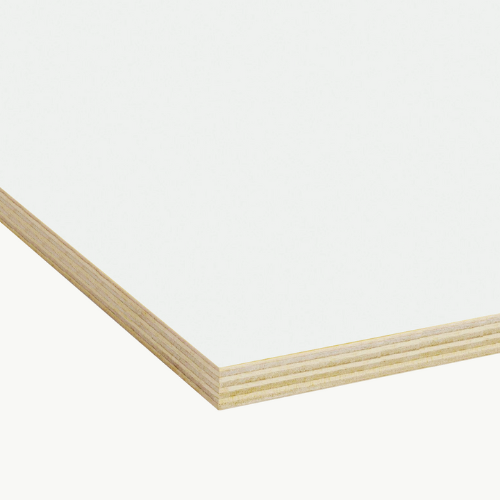

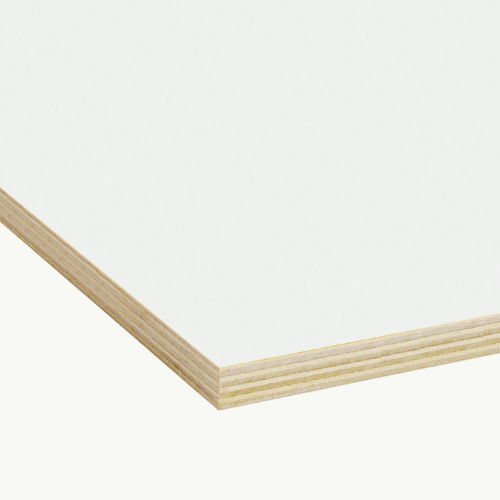

We carry our plywood in birch and white melamine finishes, stocked in 3/4", 1/2", and 1/4" thicknesses. Each sheet is built to handle whatever you're planning.

The Basics: What Is Plywood Anyway?

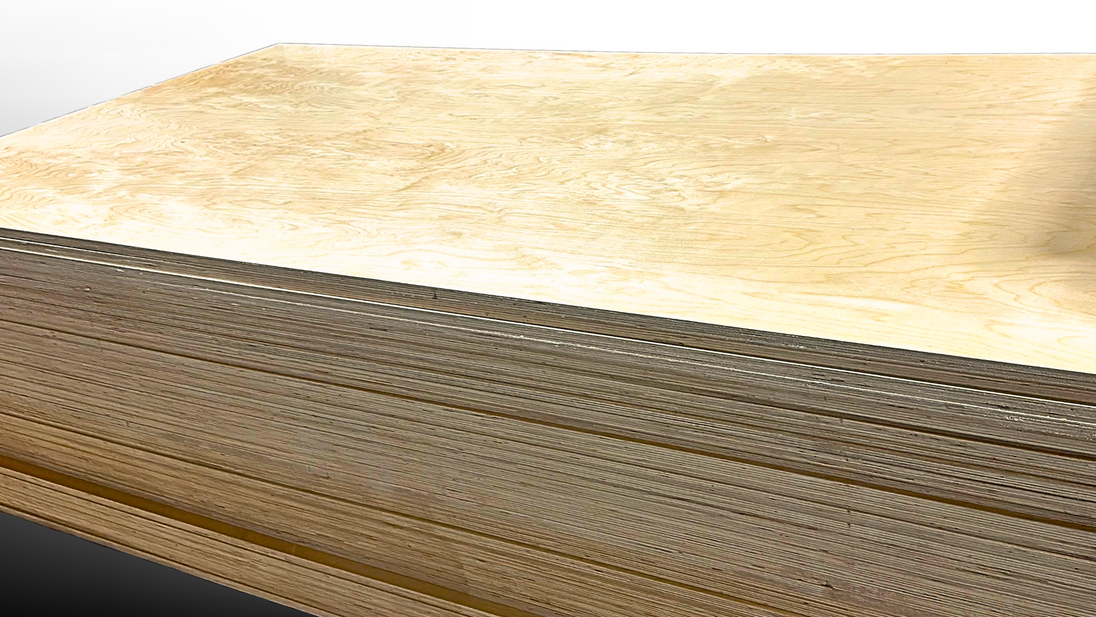

Think of plywood as nature's way of fixing wood's biggest problem – it wants to move around. We take thin wood veneers, layer them with alternating grain patterns, then bond everything under serious heat and pressure. This cross-grain construction is what stops warping and gives you that rock solid stability.

It's basically engineered wood that behaves predictably, which is exactly what you need for precision work like kitchen cabinets or furniture grade plywood projects.

How This Stuff Actually Gets Made

The process is pretty straightforward but requires serious precision. Thin wood veneers get peeled from logs (imagine unrolling a paper towel, but with wood), dried to exact moisture content, then coated with industrial-strength

adhesives.

These layers get pressed under massive pressure and heat, creating one solid panel that acts like a single piece of wood – except better, because it won't twist, cup, or bow on you six months later.

Our Two Go-To Options (And Why)

After countless conversations with customers, birch plywood and melamine plywood cover about 95% of what people actually need:

Birch Plywood – This is your classic choice. Beautiful grain that takes stain like a dream, strong enough for any cabinet application, and that warm wood look that never goes out of style. Perfect for prefinished plywood projects where appearance matters.

White Melamine – The practical workhorse. Essentially plywood with a durable white surface that won't yellow, chip, or need maintenance. Great for closet systems, pantries, or anywhere you want that clean, modern look without the upkeep.

Thickness Options That Actually

Matter

Here's what we recommend after seeing hundreds of projects:

3/4 inch plywood – Your heavy-duty option. Built with 11 plies for maximum strength. This is what you want for cabinet boxes, substantial shelving, and furniture construction. Both sides come prefinished, so you're ready to install.

1/2 inch plywood – The sweet spot for many projects. Uses 8 plies, perfect for cabinet doors, drawer fronts, and medium-duty shelving. Also prefinished both sides.

1/4 inch plywood – Your economical choice with 3 plies. Great for drawer bottoms, cabinet backs, and decorative panels. Prefinished on one side.

Why Prefinished Saves Your Sanity

Here's where we really shine compared to raw lumber. Every sheet comes with UV-cured finish already applied. What does that mean for you? No sanding, no sealing, no

dust, no mess. You literally cut, install, and you're done.

Had a contractor tell me last month this cut his kitchen job time in half. No

exaggeration.

Plywood Sheets vs. The Competition

When you research different types of plywood sheets, you'll run into terms like

softwood plywood, hardwood plywood, marine-grade, MDF core – the list goes on.

Most of that stuff is for construction or outdoor use.

We focus on high-grade interior plywood because that's what cabinet makers and

furniture builders actually need. Our prefinished cabinet plywood eliminates

the guesswork and extra labor.

The Northeast Advantage

We serve the entire region from our Pennsauken, NJ warehouse – New Jersey, New York, Pennsylvania, Connecticut, Maryland, Massachusetts, Virginia, and Delaware. Whether you're a contractor doing kitchen cabinets or a homeowner tackling garage storage, we offer pickup and delivery that actually works.

You can grab your order at 9040 Pennsauken Hwy, NJ 08110, or we'll bring it to your job site. Simple as that.

What Sets Us Apart (Honestly)

Look, you can buy cheaper plywood. But here's what I've learned: cheap plywood

usually means inconsistent thickness (your drawer slides won't work right), voids in the core (screws won't hold), and face veneers that look amateur no matter how good your finish work is.

Our cabinet grade plywood costs more upfront, but it saves you callbacks,

frustrated customers, and that sick feeling when a project doesn't turn out right.

The prefinished surfaces eliminate job site mess, our plies bond tight with zero

gaps, and every cut comes out clean because the core stays stable. Whether

you're doing drawer bottoms with 1/4" sheets or full cabinet boxes with 3/4" material, you'll notice the difference immediately.

Bulk Pricing for the Pros

Contractors love our automatic volume discounts:

10+ sheets: 10% off (applies automatically)

20+sheets: 15% off (sweet spot for most kitchen jobs)

50+sheets: 20% off (contractors love this one)

No phone calls, no haggling – the discount just shows up at checkout.

What People Actually Build With This

Our plywood shows up in all kinds of projects:

Kitchen cabinets (obviously our bread and butter)

Bathroom vanities - they always look clean and professional

Custom closets (way better than wire shelving)

Entertainment centers and built-ins

Garage storage that actually looks good

Furniture projects when you want wood that cooperates

Basically, anywhere you need plywood that looks good and lasts.

Different Grades, Different Results

This matters more than most people realize. Grade A cabinet grade plywood means

smooth faces, no knots, no voids, and surfaces ready for whatever finish you

have in mind. Grades B and C have patches, repairs, and blemishes that show

through any finish.

We stock only Grade A because that's what professional results require.

The Bottom Line

If you're building something that matters – something you want to look professional and last for years – cabinet grade plywood is worth every penny. We've built our reputation helping contractors and serious DIYers get results they're proud of.

That starts with materials that don't let you down.

Questions about thickness, finishes, or delivery?

Give us a call. We're here to help you pick exactly what your project needs.

FAQ – Product Specifications

What makes your plywood "cabinet grade" compared to other options?

Cabinet grade plywood uses Grade A face veneers with zero defects, patches, or knots, which is completely different from the B or C grade plywood you'll find at big box stores. These premium surfaces are smooth enough to accept any finish evenly without blemishes showing through.

The difference really comes down to quality control. Our cabinet grade plywood has consistent thickness throughout with no voids or gaps that cause screws to fail or drawer slides to bind. You won't deal with warping, cupping, or bowing issues that plague lower grade materials.

When you're building kitchen cabinets or custom furniture, cabinet grade plywood costs more upfront but saves you from callbacks and finish problems. Our 4x8 cabinet grade plywood sheets come prefinished, so you can choose birch plywood for classic wood grain or white melamine for a clean modern look.

What thicknesses are available and how many plies does each have?

We stock three thicknesses that handle most projects. The 3/4 inch plywood has 11 plies and comes prefinished on both sides - perfect for cabinet boxes and heavy-duty shelving. Our 1/2 inch option uses 8 plies, also prefinished both sides, which works great for cabinet doors and drawer fronts.

The 1/4 inch plywood has 3 plies and comes prefinished on one side. Most people use this for drawer bottoms and cabinet backs where you don't need the extra strength. More plies mean better screw holding power and less splitting when you're installing hardware.

What type of finish is applied to the prefinished surfaces?

We use a UV-cured finish on all our prefinished plywood surfaces. This industrial-strength coating cures under ultraviolet light, which creates a much harder and more durable surface than regular finishes you'd apply on site.

The UV finish eliminates all the mess and time of field finishing - no sanding, sealing, or multiple coats needed. You literally cut your plywood and install it. One contractor told me it cut his kitchen job time in half because there's zero finishing work once the plywood goes in. The surface is ready to go and won't yellow, chip, or need touch-ups down the road.

FAQ – Applications & Uses

What projects work best with cabinet grade plywood?

Our cabinet grade plywood handles pretty much any interior project where you want professional results. Kitchen cabinets are obviously the main use - the 3/4 inch plywood is perfect for cabinet boxes while 1/2 inch works great for doors and drawer fronts. Custom furniture builders love this stuff because the Grade A face veneers take stain evenly and look incredible.

Bathroom vanities are another popular application since our prefinished plywood holds up well in moisture-prone areas. The UV-cured finish creates a protective barrier that won't peel or bubble like cheaper alternatives. Built-in entertainment centers, closet systems, and garage storage also turn out great with our birch plywood or melamine options.

Can you use 1/4 inch plywood for cabinet doors?

Honestly, 1/4 inch plywood works better for drawer bottoms and cabinet backs rather than doors. Cabinet doors need the strength and stability that comes with our 1/2 inch or 3/4 inch furniture grade plywood. The thicker material prevents sagging and gives you better screw holding power for hinges.

Most contractors stick with 1/4 inch for non-structural applications where you need that prefinished look but don't need heavy-duty strength. It's perfect for decorative panels and anywhere the back side won't be visible.

Does prefinished plywood work in bathrooms and moisture areas?

Our prefinished plywood actually performs really well in bathroom vanities and other high-moisture areas. The UV-cured finish we use creates a much more durable barrier than field-applied finishes. You won't see the peeling, bubbling, or yellowing that happens with cheaper materials.

That said, like any wood product, you still want to seal cut edges and avoid direct water contact. The prefinished surfaces handle normal bathroom humidity just fine, which is why a lot of contractors use our cabinet grade plywood for vanity construction.

Can this plywood be used for furniture construction?

Absolutely - furniture grade plywood is exactly what this material was designed for. The Grade A face veneers and stable core construction make it ideal for tables, bookcases, dressers, and custom built-ins. Our 4x8 plywood sheets give you plenty of material to work with for large furniture pieces.

The prefinished option saves tons of time since you skip all the sanding and finishing work. Cabinet makers and furniture builders really appreciate having that consistent, professional surface ready to go. Both the birch plywood and melamine versions work great depending on the look you're going for.

FAQ – Ordering & Delivery

What are your bulk pricing discounts for contractors?

We offer automatic volume discounts that show up at checkout - no haggling or phone calls needed. Order 10 or more sheets of cabinet grade plywood and you get 10% off. Most contractors hit the sweet spot at 20 sheets for 15% off, which works perfect for most kitchen cabinet jobs. If you're doing a really big project, 50 sheets gets you 20% off.

The discounts apply to all our prefinished plywood - birch, melamine, whatever thickness you need. Contractors love this because they can stock up on 4x8 plywood sheets and save money while having materials ready for multiple jobs.

Do you offer delivery and what areas do you serve?

Absolutely - we deliver cabinet grade plywood throughout the entire Northeast from our Pennsauken, New Jersey warehouse. We cover New Jersey, New York, Pennsylvania, Connecticut, Maryland, Massachusetts, Virginia, and Delaware with reliable delivery that actually shows up when promised.

Can I pick up my order at your warehouse?

Sure can - pickup is always free at our warehouse at 9040 Pennsauken Hwy, NJ 08110. We'll help you load your cabinet grade plywood right into your truck, so you don't have to worry about handling those prefinished surfaces and potentially damaging them.

A lot of local contractors prefer pickup because they can swing by on their way to the job site and grab exactly what they need. Plus you can inspect the birch plywood or melamine sheets before you take them.

How long does delivery take for plywood orders?

Most cabinet grade plywood orders deliver within 2-3 business days throughout our service area. If you need your prefinished plywood on a specific day for your kitchen cabinet project, just give us your order number and we'll coordinate the timing.

For rush jobs or large furniture grade plywood orders, we can often expedite delivery to keep your project on schedule. We know contractors can't afford to wait around when they're ready to install.

FAQ – Installation & Working Properties

Do I need to sand or seal the prefinished surfaces before installation?

Nope - that's the whole point of prefinished plywood. Our UV-cured finish is already applied and ready to install. No sanding, no sealing, no mess. You literally cut your cabinet grade plywood and install it. One contractor told me it cut his kitchen job time in half because there's zero finishing work once the plywood goes in.

The prefinished surfaces on our birch plywood and melamine sheets are tougher than anything you'd apply in the field, so you're actually getting better protection than if you finished it yourself.

Will screws and hardware hold securely in this plywood?

Absolutely - our cabinet grade plywood has excellent screw holding power because of the solid core construction. The 3/4 inch plywood with 11 plies gives you maximum strength for cabinet boxes and heavy-duty applications. Even our 1/2 inch furniture grade plywood with 8 plies holds screws really well for doors and drawer fronts.

You won't deal with the voids and gaps that cause hardware failures in cheaper plywood. The consistent density throughout each 4x8 sheet means your hinges, drawer slides, and cabinet hardware will stay put for years.

What's the best way to cut prefinished plywood without chipping the finish?

Use a fine-tooth blade and score the cut line first with a utility knife. The key is supporting both sides of the cut and going slow - don't rush it. A lot of contractors tape the cut line before cutting to prevent any chips in the prefinished surface.

For circular saws, cut from the back side since most chips happen on the exit side of the blade. With our UV-cured finish, it's pretty durable, but taking these precautions keeps your birch plywood or melamine looking perfect.

Do you provide cutting services?

Usually we don't provide custom sizes, but if you need sheets cut to fit in your truck, we can help out. We can also cut 4x8 plywood sheets in half for easier transport - basically half and half dimensions.

Most contractors prefer getting full sheets of cabinet grade plywood anyway since they can cut exactly what they need for each application. But we understand sometimes you need smaller pieces to make pickup and delivery work with your setup.